www.electronics-usa.com

17

'23

Written on Modified on

TDK News

TDK IMPLEMENTS TEMPERATURE SENSING OF LED FLASH WITH NTC THERMISTOR

The NTC thermistor is a thermally sensitive resistor that can be utilized in various applications such as temperature sensors and thermal protection devices to protect circuits from overheating.

The NTC thermistor is a thermally sensitive resistor whose resistance decreases rapidly as the temperature rises. This property can be utilized in various applications such as temperature sensors and thermal protection devices to protect circuits from overheating.

By mounting the NTC thermistor in close proximity to the heat source, it can accurately sense the temperature of the heat source. However, in some cases, such as when there are constraints on the size of the board or the pattern layout, it may need to be mounted in a location away from the heat source.

Considering such conditions, TDK used the LEDs on the LED flash circuit board as the heat source and simulated heat generation to check the temperature difference between the LEDs and the NTC thermistors caused by the different mounting positions. It also checked the effect of circuit board thickness.

Objective

By mounting the NTC thermistor in a position closer to the heat source, it is possible to sense the temperature of the heat source accurately. However, there are cases where the NTC thermistor must be mounted at a distance away from the heat source due to constraints such as board size and pattern layout.

In case of the LED module in the LED flash board as the heat source, we checked the temperature difference caused by the difference in the mounting positions of the LED and NTC thermistor using a heat generation simulation software (PICLS - Provided by Software Cradle Co., Ltd.). We also checked the effect of board thickness.

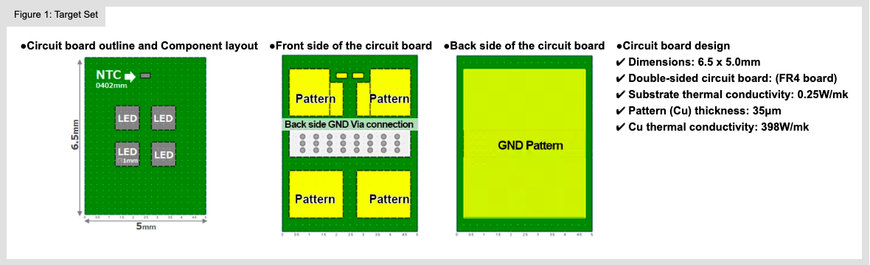

Target Set

Create a simulation model of the circuit board based on the design of a LED flash board for smartphones.

- Circuit board dimensions:6.5 x 5.0mm

- LED Dimensions:1.0 x 1.0mm

- LED Output:30mW x 4 pieces

Simulation Conditions

Below are the conditions for the simulation.

Condition 1: Circuit board thickness

- In the LED flash board, the GND pattern on the front side is connected to the backside through via.

- Main material of the circuit board is FR4.

- The thicker the circuit board, the more FR4 material is used.

- The board thickness is set to two cases: 0.4mm and 1.6mm.

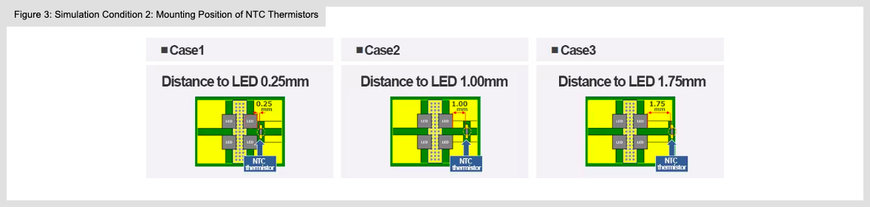

Condition 2: NTC thermistor mounting position

- Four 1mm-sized LEDs are mounted in the centre of the LED flashboard.

- EIA01005(0.4x0.2mm) NTC thermistors are placed at a distance away from the LEDs.

- The NTC thermistors are mounted at a distance of0.25mm, 1.00mm, and 1.75mm from the LEDs.

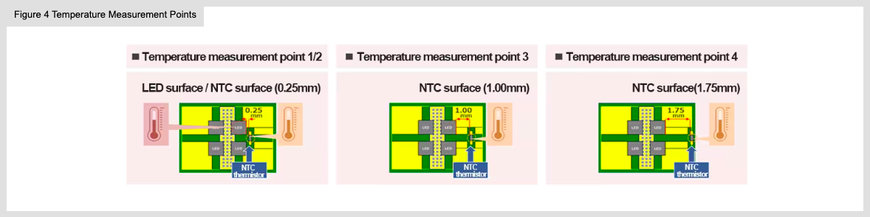

Temperature Measurement Points

During the heat generation simulation, four temperature measurement pointswere set on the surface of the LED and the NTC thermistor.

Simulation Results

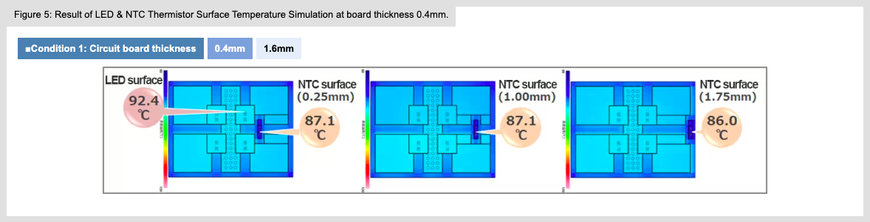

Result 1: 0.4mm board thickness

- The LED surface temperature reached 92.5℃.

- The NTC thermistor surface temperature decreased as the distance from the LED became farther.

- There was a temperature difference between the surface temperature of the NTC thermistor and the LED.

- There was a temperature distribution on the circuit board surface, and a temperature difference also occurred between the conductor pattern and FR4.

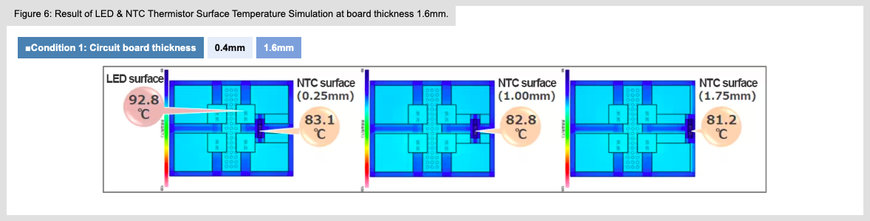

Result 2: 1.6mm board thickness

- The LED surface temperature reached 92.8℃.

- The NTC thermistor surface temperature decreased as the distance from the LED became farther.

- There was a temperature difference between the surface temperature of the NTC thermistor and the LED.

- There was a temperature distribution on the circuit board surface, and a temperature difference also occurred between the conductor pattern and FR4.

Summary of heat generation simulation results

- Temperature difference depending on the NTC thermistor mounting position:

- It difficult for heat from the LED to be transferred to the surrounding area, because FR4 has low thermal conductivity like 0.25W/mk.

- The result of this simulation has the temperaturedifference between the LED and the surrounding area.

- The temperature difference between the LED and the NTC thermistor increases as the distance from the LED becomes farther.

Conclusion on the effect of board thickness: The results for boards of different thicknesses show that thicker board lead to increased temperature differences between the LED and the NTC thermistor.

Temperature Sensing Circuit Using NTC Thermistors

- In case of the circuit board material with FR4, the heat from the heat source does not expand easily to the surrounding area.

- Then, there is the temperature difference between the LED and the surrounding area.

- In addition, the further away from the heat source, the bigger the temperature difference between the heat source and the NTC mounting position.

- When designing a temperature-sensing circuit, these phenomena need to be taken into consideration.